High Quality Stone Jaw Rock Stone Calcium Carbide Crusher

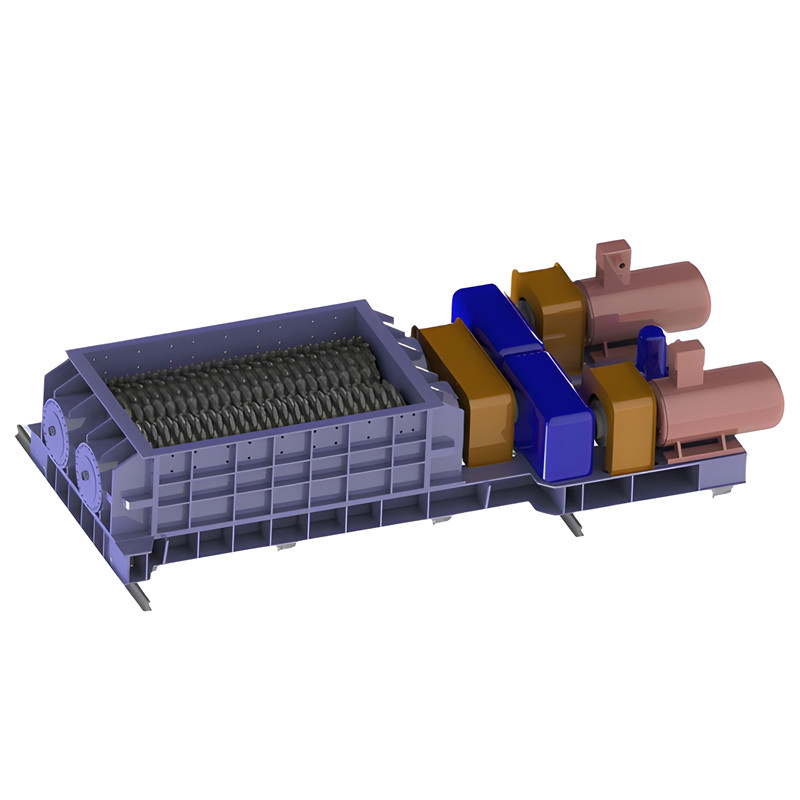

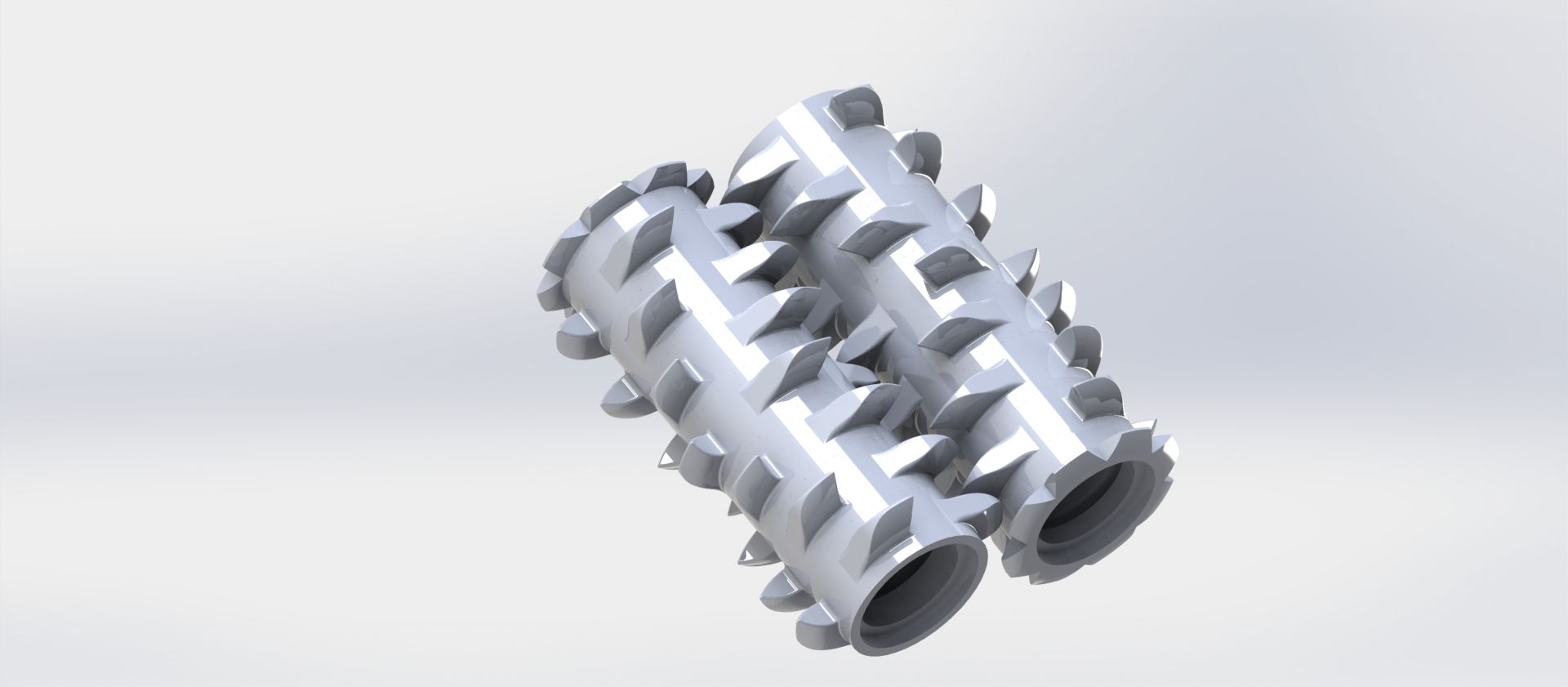

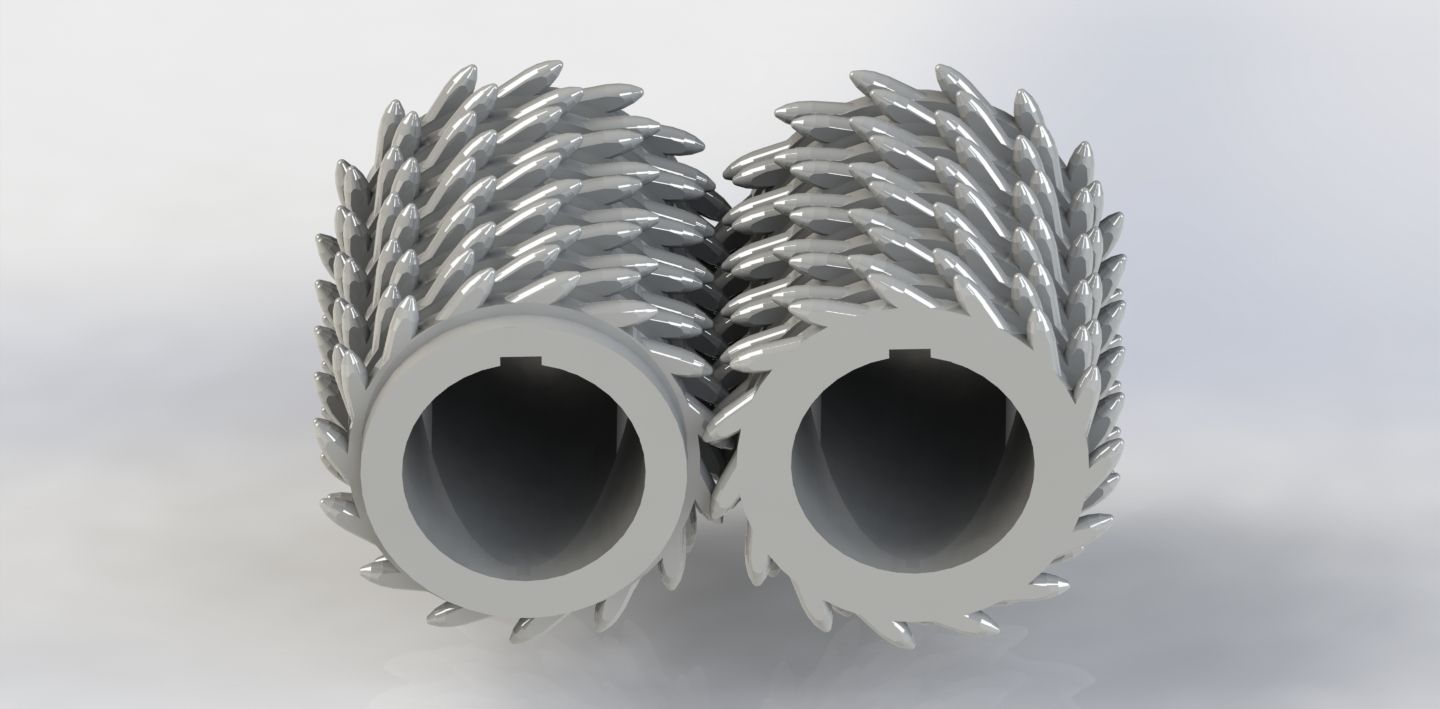

CALCIUM CARBIDE CRUSHER TOOTH PROFILE

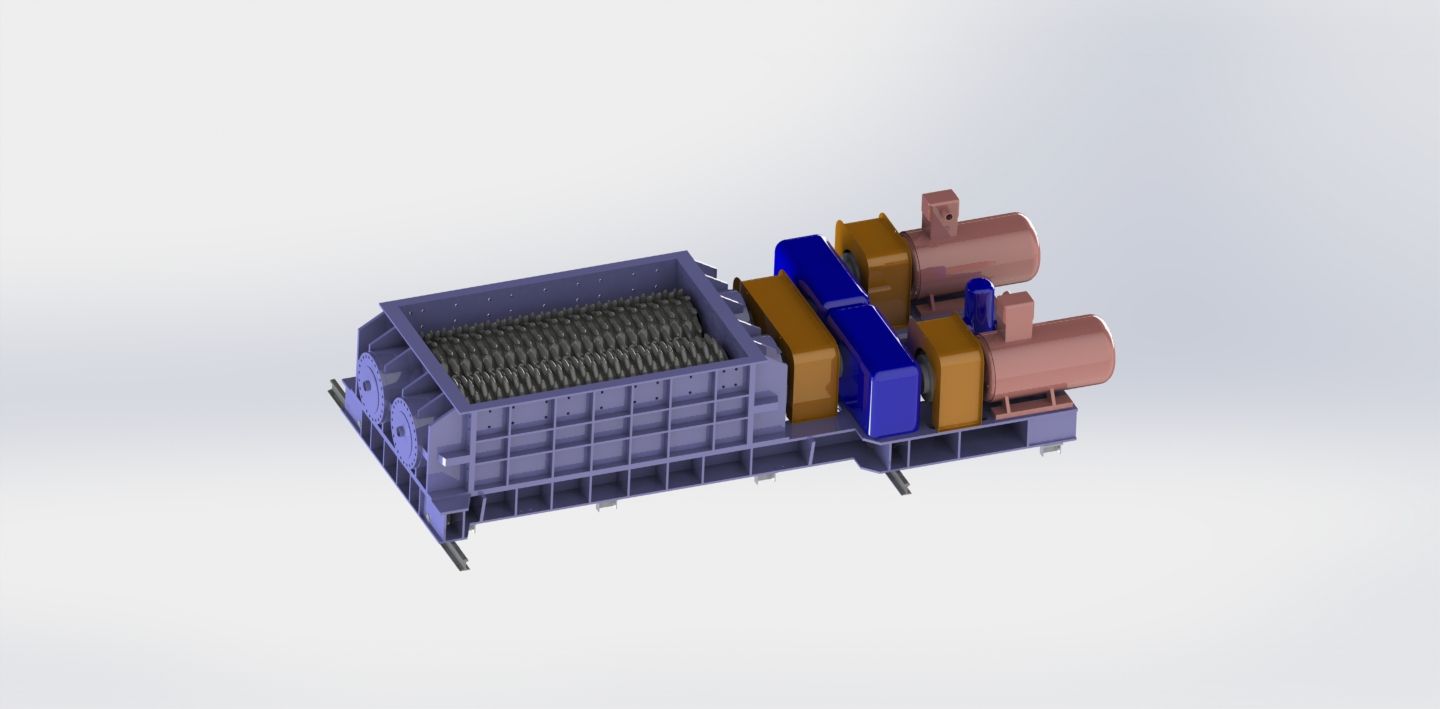

CALCIUM CARBIDE WORKING PRINCIPLE AND STRUCTURE

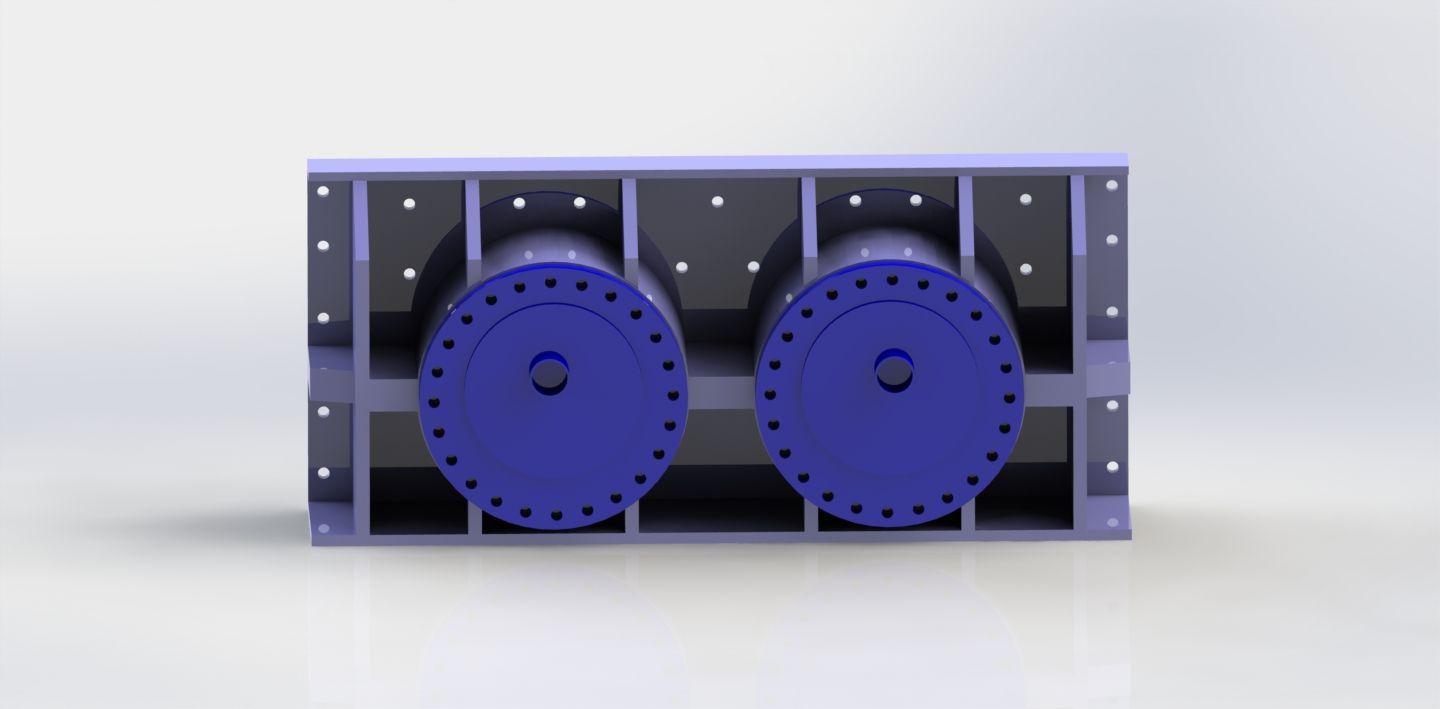

In order to maximize the rate of calcium carbide lump forming, the shape of crushing teeth adopts olecranon and bullet type. The unique spiral arrangement of crushing teeth and the elevation angle of crushing teeth are designed. Under the premise of ensuring the strength of crushing teeth, the clamp materials capacity of crushing teeth can be improved to the greatest extent. Under the condition that the center distance between the two teeth rollers is certain, the gap formed between the teeth makes the crushed material in line with the discharge particle size discharged from the lower part of the crusher frame. The shape of the teeth determines the shear and splitting effect of the tooth tip on the material after the crushing material, so that the material is crushed. Double-toothed roll crusher has the double function of screening and crushing, its crushing principle determines its high lump rate, low over crushing rate, good material type and so on.

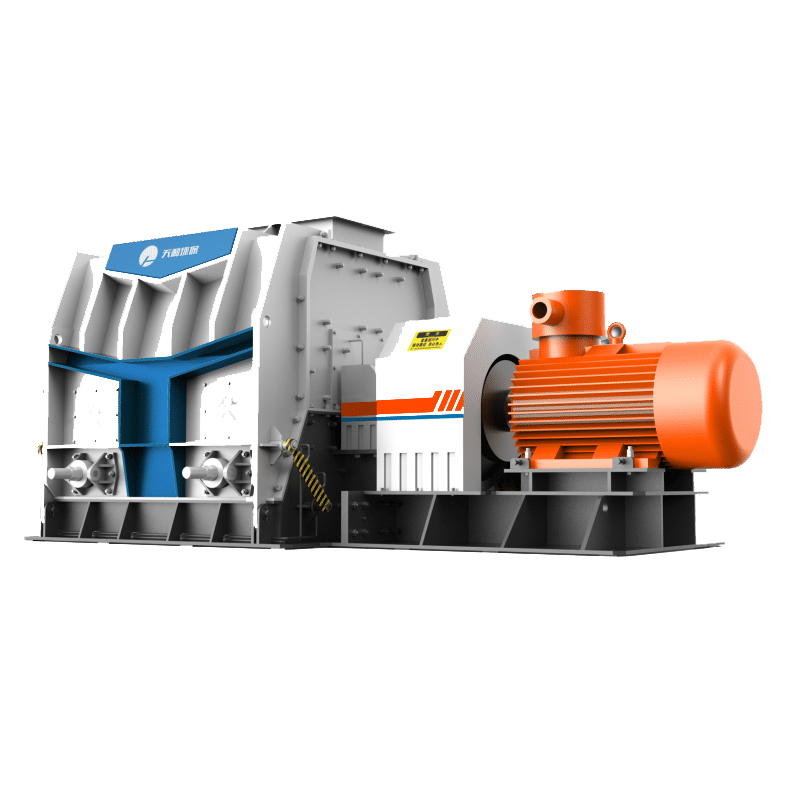

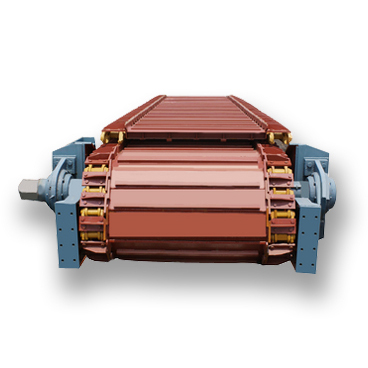

PRIMARY CRUSHER

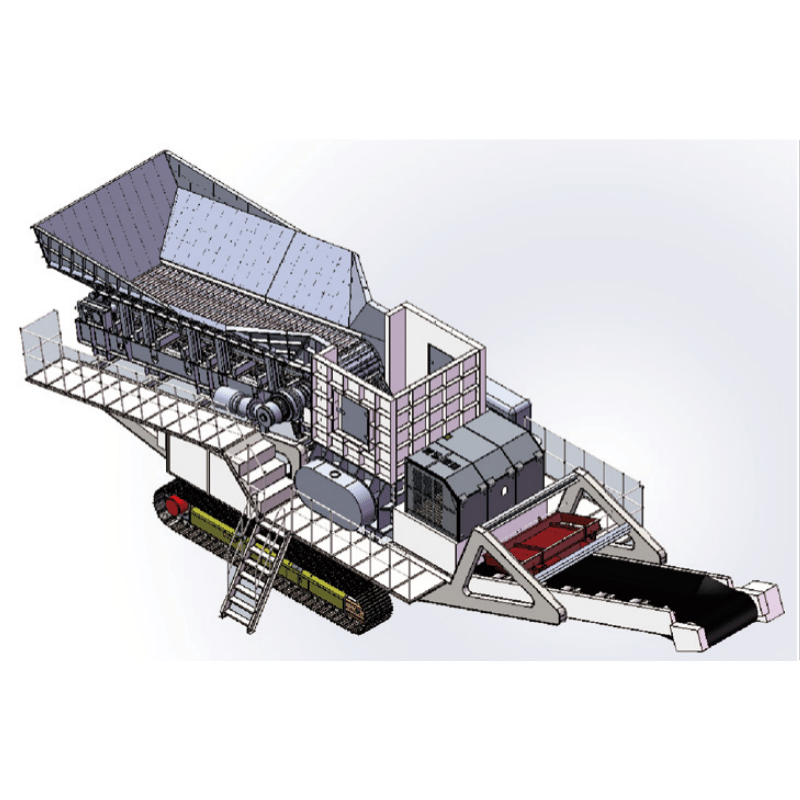

SECONDARY CRUSHER

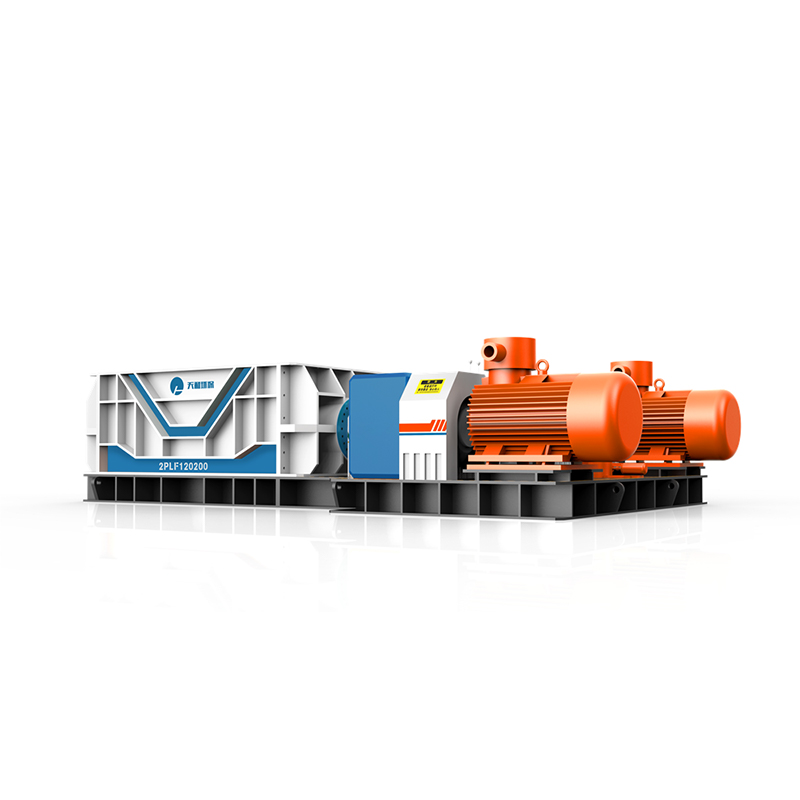

CALCIUM CARBIDE CRUSHER DISCHARGE SIZE ADJUSTMENT DEVICE

Calcium carbide crusher is directly driven by motor, hydraulic coupler, reducer and pin coupling, bearing seat is fixed with rigid eccentric device (using bolts), if the discharge material size can not meet the technical requirements, adjustable eccentric cup circumference position, to adjust the discharge material size. This structure can meet the process requirements of similar discharge size, or maximize the use of the tooth roller due to wear. The rigidity of the eccentric device can be adjusted, firstly to ensure the stable performance of the crusher equipment in the crushing process, and secondly to meet the requirements of the user to the maximum extent of different discharge process requirements.

ECCENTRIC DEVICE (Adjust the center distance structure)

CALCIUM CARBIDE CRUSHER PROTECTION SYSTEM

1, pin coupling cutting pin protection. When the instantaneous impact of the crusher is too large, the pin will be cut off to protect the motor and reducer and other driving parts.

2, hydraulic coupler spray protection. When the crusher instantaneous impact is too large, but the pin is not cut off, the hydraulic coupler motor rotation, tooth roller stop rotating, hydraulic coupler oil temperature will rise rapidly, resulting in fusible plug melting, oil from fusible plug ejection, thus cutting off the transmission between the motor and reducer. To protect the motor and reducer transmission components.

3, the speed sensor electrical protection, crusher factory set the crushing roller loss parameters, when the design parameter value, when the signal reaches the control cabinet to react, the motor power supply will stop.